WFP-X Innovation Accelerator

with WFP Innovation Accelerator & Project Concern International

WFP-X was the first ever exploration of moonshot innovation for urban food security in 2030 megacities, aiming to build a novel approach to generate 100 ambitious moonshot ideas in 100 days to radically reshape the future of the urban food system, starting with Dar es Salaam. I was one of 9 innovators in the accelerator and I designed the top 5 finalist moonshot solution, Forever Food.

To learn more about the innovation program, visit https://innovation.wfp.org/wfp-x

To access the innovation toolkit, visit https://innovation.wfp.org/wfp-x/moonshot-toolkit

Background

As one of the fastest growing cities globally, Dar es Salaam’s population is expected to increase by 59% in 10 years, from 7 million to 12 million—a growth rate that could make it the world’s third largest city by 2100. It is estimated that 5 million people might be unable to access the food they need for a balanced, nutritious diet by 2030. To address this impending crisis, the WFP Innovation Accelerator, in partnership with the WFP Innovation Hub Tanzania and Project Concern International, launched WFP-X, bringing together innovators from different backgrounds, including software engineering, microbiology, nutrition, urban planning, farming and behaviour change.

Within 3 months of the moonshot innovation journey, we generated 100 ideas to strengthen food security. The following months involved continuous falsification, rapid prototyping and co-creating with the user. At the end of the journey, the team showcased 5 strong high-fidelity prototypes that are currently ready to go to market - one of them being my idea and design, Forever Food.

Summary Video

Phase 1 - Huge Problem

Main Goal:

To cultivate a deep understanding of urban food security in Dar es Salaam.

Step 1: Ecosystem Mapping

In order to better understand the Huge Problem for which we were attempting to solve, we had to first map the entire food system of Dar es Salaam.

Step 2: Develop Falsification Criteria

We then developed KPIs for our falsification criteria before we began the design process to ensure that our solutions are both imaginative and inspiring but also grounded in data, science and credible technological advancements. Our falsification criteria was:

-

Consumption of diets that are nutritious, affordable and proximate to the poorest of Dar es Salaam’s consumers in periods of stability and crisis.

-

The means of production, processing and distribution are efficient, abundant and inclusive.

-

The whole of system and its components result in a net-zero or net-positive impact on the land, water and air upon which it depends.

Step 3: Stakeholder-Problem Fit

We then did the first round of research with the following objectives:

-

Validate most critical stakeholder problems worth solving

-

Obtain feedback on the food system map

Methodology:

Digital ethnography followed by 21 moderated interviews in total by all innovators. I interviewed 3 stakeholders, including a small scale chicken farmer, a restaurant manager and a small scale fruit vendor.

Key Insights:

-

Small scale chicken farmers employ unhealthy hacks to make chicks grow faster to sell quickly or skip on vaccination costs

-

Restaurant managers choose suppliers based on values other than cost like animal produce being ‘halal’

-

The cost of food exponentially increases after packaging and processing

Impact:

-

The insights led us to refine our map and add missing stakeholders like packaging and processing companies, and animal vaccinators.

Phase 2: Radical Solution

Main Goal:

Employ big, bold, out of the box thinking to create 100 moonshot solutions to the big problem.

Step 1 - Prioritising Problem Areas

The start of Phase 2 called us to revisit the problem set so that we could break down the huge problem to 7 priority areas that are measurable, before we began ideating. By analysing key performance indicators and trendlines, as well as detailed mapping and annotation of the Dar es Salaam food system value chains, the following huge problems emerged:

-

What you reap is not what you sow

-

Gone too soon - Post harvest loss

-

Long journey to short shelf-life

-

Diets that fail to nourish the planet nor the body

-

High cost of eating right

-

Cooking your food and the planet

-

Wasted waste

Step 2 - Ideation

Next, we sourced inspiration from frontier technologies and researched what was already working well in other countries. Each innovator then had to generate two ideas for each problem area. The ideas involved rough sketches and were uploaded on Airtable weekly until we met our goal of 100 moonshot ideas.

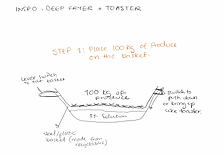

This is one of my first sketches for Forever Food - one of the 5 ideas that made it to the final. I came up with this idea after reading about a lab study done in Malaysia showing that gum arabic can extend the shelf life of some fruits and vegetable for up to 20 days. The solution had not yet been used at a large scale but I saw the possibility because acacia trees that produce gum arabic grow in Tanzania.

Step 3 - Iteration & Falsification

Each week, our ideas would be presented to the rest of the team to start iterating. The iteration questions looked like:

-

How could we level up the product?

-

What could we remove from the solution to improve it?

-

How could we make this accessible to the most low-income consumer in Dar?

-

How could we make this idea become a staple food?

Each innovator then had to go back to their idea and add the suggestions while also proving that the idea met our KPIs. The WFP-X team put all the ideas to the test and picked the top 15 ideas from 100.

3 of my ideas made it to the top 15: Forever Food, Daima and Our Shamba.

Step 4 - Pitching

We had to pitch the top 15 ideas to a panel of judges who then picked the top 6 ideas that would move on to Low-Fidelity Prototype stage. The pitching session was done on Zoom with judges from all over the world, including Dar es Salaam, Nairobi, Johannesburg, Brussels, New York and Munich.

This picture on the right shows me pitching one of my product ideas but it didn’t make it to the final 6. My other idea ‘Forever Food’ made it to the final and I began prototyping and testing in the next phase.

Phase 3: Breakthrough Approach

Main Goal:

To build low to medium fidelity prototypes of the final 6 ideas to determine feasibility and iterate quickly. In this section, I will focus on the work that what I did with Forever Food as I led the design and research.

Step 1: Systems Research for Gum Arabic Preservative

Research Objectives:

-

Validate buyer’s interest in the gum arabic preservative

-

Understand who has the most need for the preservative on the food supply chain

Methodology:

-

Qualitative interviews

-

I interviewed 8 different stakeholders ranging from transporters to small scale fruit and vegetable vendors at local markets

Key Insights:

-

All transporters and most vendors are not interested in extending the shelf life as they get paid their due regardless

-

The way fruits and vegetables are packaged currently will not allow for a spraying system to be in place on the trucks as they are stacked up high

-

Fruits do not stay more than four days at the market - over 30% spoil and the rest are sold

-

Every day there are more than 20 trucks arriving in the country

Impact:

From the interview insights, I was able to make the following important changes to Forever Food's business model:

-

Since it was best to apply the solution directly after harvest, the best person to work with was the owner of the produce as they have a vested interest in making sure that the produce is of best quality so that they make a profit

-

The prototype user testing should be done with producers

-

Introduce stickers on the produce to foster relationships with retailers

First business model:

Gum arabic spraying in trucks during transportation

Updated business model:

Gum arabic application immediately after harvest

Step 2: Medium Fidelity Prototyping

Due to shortage of time and budget limitations, I simultaneously led two research studies for the medium fidelity prototype stage.

Study 1: Effectiveness of Gum Arabic in Extending Shelf Life of Fruits and Vegetables

Research Objectives:

-

Prove that the solution extends shelf life of fruits and vegetables by up to 20 days

-

Test sustainability and feasibility of locally producing the solution

Methodology:

-

Worked with Masters students at Sokoine University to develop the solution

-

Conducted a controlled lab experiment with tomatoes and green peppers straight from harvest

-

Took pictures of the produce for 20 days

Key Insights:

-

Gum arabic preserved tomatoes for 20 days and green peppers for 18 days

-

Gum arabic preserved the nutrient content and colour of the produce

-

Best results are found when the produce is dipped in the solution and left to dry vs. spraying

-

The solution works on fruits and vegetables that are cut and then put in the fridge, which opens the door to individual consumer market

Study 2: Research Gum Arabic Production and Logistics

Research Objectives:

-

Learn about the process and costs of harvesting gum arabic in Tanzania

-

Identify regions fit for planting acacia trees

Methodology:

-

Unstructured interviews with gum arabic farmers

-

Site visits in Same, Kilimanjaro region

Key Insights:

-

Gum arabic is not used locally for preservation but is exported for medicinal purposes and used for soda production

-

1 acacia tree can produce 10 kgs of gum arabic in 3 months

-

Gum arabic sold in markets is expensive. In order to produce the solution at scale, we need to plant many acacia trees as we can only harvest 10 kg of gum arabic per tree in 3 years

-

Same proved to be a fit area to plant acacia trees due to the arid climate

Impact from both Studies:

-

The idea was awarded $5000 and moved to High-Fidelity Stage

-

Partners began communication with local gum arabic farmers

-

Name Change from ‘Food Gone Good’ to ‘Forever Food’

Phase 4: Tethered to the Possible

Main Goal:

Co-creating with the user by building high fidelity prototypes conducting multiple rounds of user testing. Previous study findings indicated that there was a real need to solve the problem of post-harvest loss for producers. Forever Food proved to be that solution in the lab but could it provide the same results with a large amount of produce and how many different types of fruits and vegetables did it work for? The goal of the high fidelity prototype was to prove the effectiveness of gum arabic in extending shelf life at scale and readiness to go to market.

Key Assumptions to Test:

-

Gum arabic solution extends shelf life of at least 30% of local fruits & vegetables

-

Building the application equipment will cost less than $200

-

Producers will understand how to use the application equipment

-

Producers are willing to pay $20 for 22.5L of solution

-

Retailers will value the Forever Food sticker and agree to buy exclusively from our producers

Step 1: Testing the Application Process

Research Objectives:

-

Learn the best way to apply the gum arabic solution to a large amount of produce

-

Observe producer staff's use and understanding of the solution

Methodology:

-

Partnered with a medium scale producer to provide fruits and vegetables

-

Produced gum arabic solution in bulk for application and to test shelf life of the solution itself

-

Produce included 20 kgs of tomatoes, 20 kgs of carrots, 20kgs of passion fruits, 20 kgs of mangoes, 20 kgs of bananas, 10 kgs of avocados, 10 kgs of eggplants, 10 watermelons

-

Application was done by dipping the produce in a basin full of solution and then transferred to a mat

-

I monitored the produce for 20 days

Key Insights:

-

The rate of spoilage was accelerated for all produce; most produce started spoiling within 5 days

-

In order for the produce to dry completely after application, all of the fruits and vegetables need to be laid out in a single layer

-

Over handling of the produce during application introduces contaminants and physically tampers the fruit or vegetable

-

-

The gum arabic solution lasted up to 3 days without cold storage

Impact:

-

The insights from this experiment informed my design of an application equipment that would be hands-free and able to dry the produce in a single layer.

Step 2: Designing the Application Equipment

In order to sketch the application equipment, I explored the city to observe the different tools used to handle large amounts of food. My inspiration came from observing how street food vendors fry large amounts of potato chips.

High Fidelity Prototype of the Application Equipment:

Final Sketches of the Application Equipment:

Step 3: Re-testing the Application Process

I repeated the entire experiment using the application equipment, allowing the produce to dry completely before monitoring.

Results:

-

The gum arabic solution worked successfully with all the 8 different produce

-

The application equipment worked well and was intuitive to use for producer staff

-

Partnered with a retailer who was willing to sell the produce with the Forever Food sticker

-

The sticker raised a lot of interest with consumers who were excited to learn about gum arabic

-

Forever Food is currently funded and being prepared to go to market with large scale producers

Step 4: Final Showcase

The top 5 ideas were showcased at The Terrace, Hotel Slipway in Dar es Salaam on 29th April 2021. The WFP-X team demonstrated the entire moonshot process to development and innovation stakeholders, while the innovators presented the final ideas. Forever Food raised funding interest from 3 organisations and received 1 offer.

Reflection

-

Prototype simply and quickly

Prototypes save time and money and are critical to the design process. When designing the application equipment, I learned that it was better to build a prototype using low-cost material to prove the effectiveness of the product rather than focusing on the more complicated technologies and features that were above budget at the time.

-

Resources are everywhere

When I had to develop the gum arabic solution, I felt overwhelmed and I didn’t know where to start. I thought I had to work with an expensive lab but I learned that there are always cheaper and simpler options like working with graduate students who could do the experiment for credit.